Creating Transparent

Supply Chains For Connected Consumers

Build Better Relationships With Your

Vendors & Suppliers

Brands, Factories & Retailers

Choose Us

Because we solve significant & important challenges

- Supply chain resilience, transparency & sustainability

- Multi-tier supply chain visibility, traceability & collaboration - Tier 1 to Tier X

- New & ever-evolving legislative mandates (AGEC, UFLPA)

- CSR & supplier compliance

- Real time chain of custody mapping

- Quality, lab tracking & inspection

- On time performance (OTIF) & booking compliance

Our AI is our secret sauce

Powered by AI, Pivot88's turnkey PAAS integrates all of your data regardless of its original source, providing actionable insights in realtime and alerting you to risks.

Learn more

“Digital allows us to trust and connect with our supply chain, our design and development teams, our legal teams, and our customers. I can't imagine how we could have done this manually."

Unlock the full story

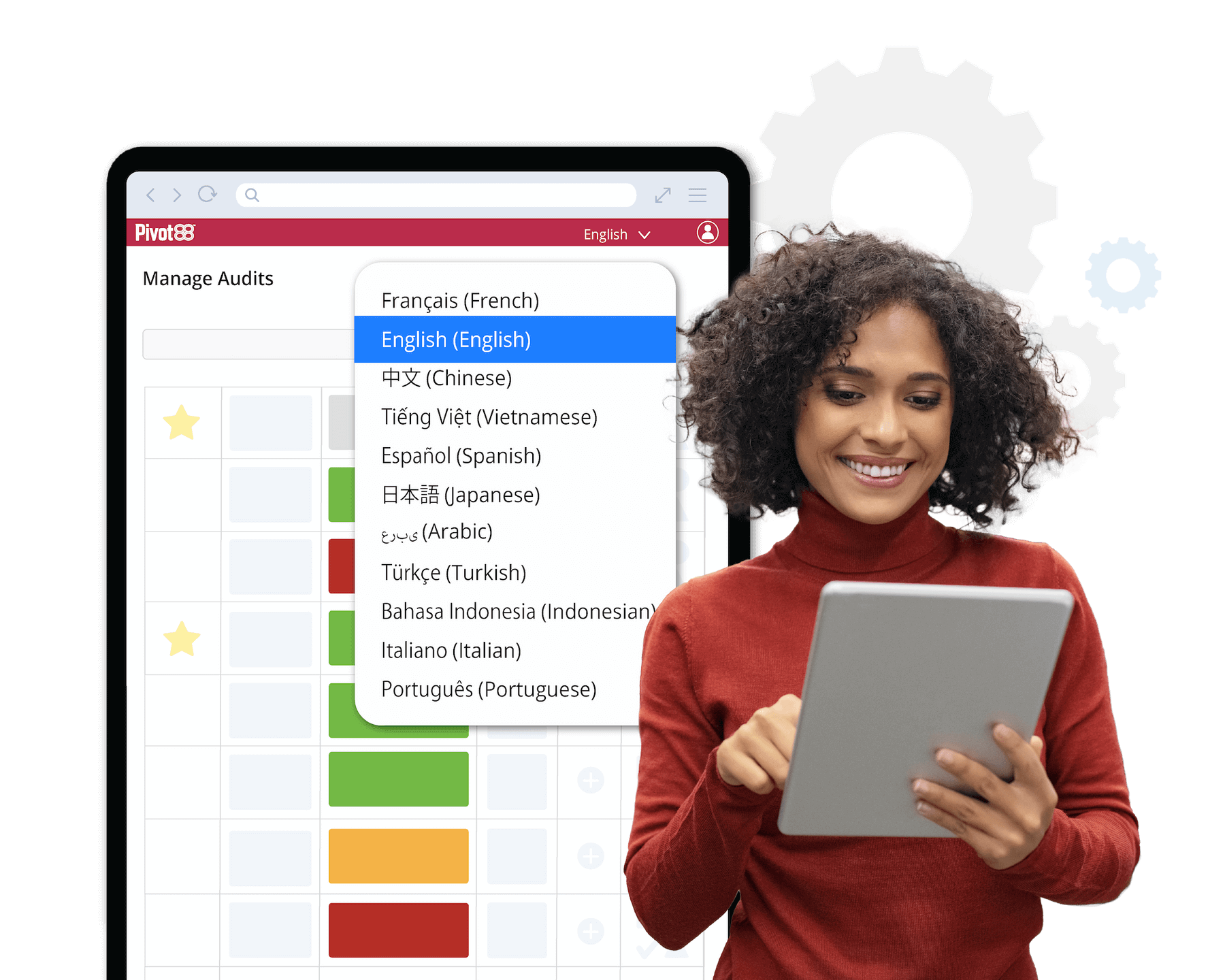

Fast & easy implementation

Available in 11 languages, with an intuitive and user-friendly interface, Pivot88 is the only platform that can get you up & running in as little as 4 weeks. We lead a digital revolution with technology that transforms.

De-risk your supply chain with Pivot88 today.

Meet our experts

As Industry Experts, We Love To Share Our Know How

Pivot88 Joins Forces with TradeBeyond

TradeBeyond, the leader of extended supply chain management solutions for private label and branded merchandise, announced today that it has acquired Pivot88, the trusted SaaS provider of quality, compliance, and...

Read more

Celebrating Women In Tech

In celebration of women in tech, we are delighted to shine a spotlight on the remarkable achievements of women in the workforce, while also acknowledging the persistent gender disparities that exist globally. At Pivot88...

Read more

How Brands & Retailers Can Better Prepare for Regulatory Action

Understanding your supply chain after T1 can be a difficult task - it is a significant challenge to gain visibility upstream and trace a specific purchase order or product’s complete chain of custody...